How can we revive creativity in our classrooms?

STEM education is vital for our nation’s future – but not without the arts, too, insists Marcus-Alexander Neil…

Anyone with their finger on the pulse will be aware of the current shift in schools’ focus away from ‘creative’ subjects such as art, design and music, in favour of core options like maths, science and English.

In fact, the continued focus on performance tables and the impact of cuts on school funding mean that overall, maths and science make up more than half of lesson time for 14-16-year olds.

Many schools are struggling to teach a wide curriculum – a recent BBC survey revealed nine in every 10 schools are cutting back on lesson time, staff or facilities in at least one creative arts subject.

Ofsted has recently acknowledged the situation, with Chief Inspector Amanda Spielman saying schools have ‘lost sight of those things that are harder to measure’.

And to compound the challenge, schools are being pressured to ensure 90% of students sit the English Baccalaureate (EBacc), which excludes any arts subjects, by 2025.

Shell has been supporting STEM education for over 50 years, because having access to a healthy pipeline of scientists and engineers is critical to businesses throughout the sector, and for tackling the big energy challenges of the future.

There’s a well-documented predicted shortfall of 59,000 engineering graduates and technicians on the horizon; so surely, a laser focus on core STEM subjects in schools is good news for an industry looking to inspire and support the future generation of engineers and scientists?

The tactile gap

In reality, though, not prioritising creative learning and subjects could have a negative impact on students’ ability to succeed in STEM related roles now and in the future.

Alice Barnard, chief executive of the education charity the Edge Foundation, says that our current approach to education is ‘not fit for purpose to tackle a 21st-century economy’.

It’s not just employers from the creative industries expressing concern about the impact it’s likely to have on the talent pipeline, but those across all industries.

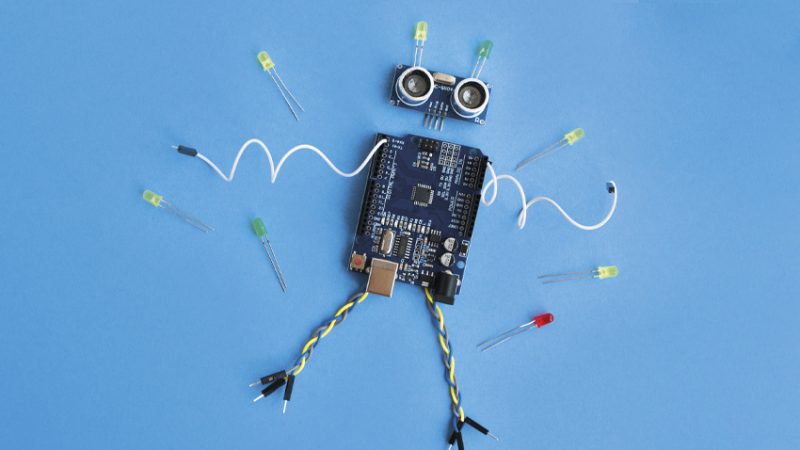

Creative subjects help students develop tactile skills, enabling them to work comfortably with their hands and become creative ‘digital makers’ and potentially innovators of the future.

‘Tactile general knowledge’ can be achieved through less of a focus on exam results and a shift to creative learning, as well as practical activities which bring ideas to life by sketching, designing and building.

Robert Kneebone, professor of surgical education at Imperial College London, has warned about the loss of medical and science skills amongst students, including the ability to manipulate laboratory tools such as a pipette, commonly used in chemistry, biology and medicine.

He cites an example of “a surgeon needing some dexterity and skill in sewing or stitching”.

As schools teach the core subjects theoretically rather than practically, students may be achieving high exam grades but still lack ‘tactile general knowledge’ and struggle even to conduct chemistry experiments.

More generally, art and design subjects also provide students with an opportunity to apply creative problem-solving skills in a variety of situations, providing them with a more rounded approach to learning in STEM subjects now and, eventually, in the workplace.

Finding solutions to the big challenges faced by the world today will require holistic thinking and people who can collaborate across subject silos; providing students with an opportunity to become fluent across specialisms will better equip them for collaborative workplaces of the future.

Real challenges

So how can businesses provide teachers and students with opportunities to apply practical skills and creativity in a way that fits within the highly pressurised, core-subject-focused system?

One way is by integrating practical and real-world skill development into these subjects through resources that link to the curriculum, making it easy for teachers to build creative learning into their STEM lessons.

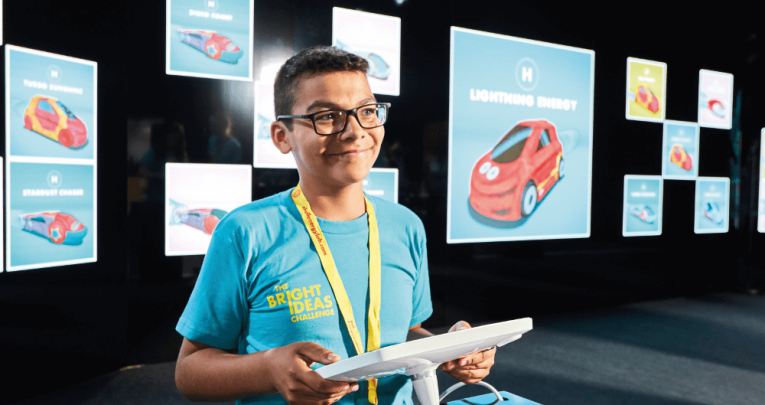

The Bright Ideas Challenge, Shell’s cross-curricular schools’ competition, invites secondary students aged 11-14 across Great Britain to imagine creative ideas to power cities of the future, ensuring they are healthy, vibrant and clean places to live.

As part of the competition, winning teams get to take their theoretical ideas and learning to a practical level, through an exciting prototyping session at Imperial College London’s Reach Out Makerspace.

With the help of professional design engineers, students apply their STEM and creative skills to build their idea into physical mock-ups.

This process requires innovative thinking and artistic skills, as well as adept problem-solving techniques.

This model is then used as the basis to design a CAD image, which is 3D printed and submitted to the judging panel – a process that replicates the work of real, cutting-edge engineers like Dyson.

The decline in creative subjects being taught in schools, paired with the challenges presented by EngineeringUK’s predicted shortfall of engineering graduates and technicians, means we need to think creatively to ensure students are leaving school with the ‘tactile general knowledge’ they need.

This is key to succeeding in a range of professions, from the creative industries to science, medicine and engineering.

By building practical skills within an exciting and hands-on environment, students will be prepared to excel in the 21st-century workplace.

Hands-on design tips

Translate the design prototyping process into classroom activities across the curriculum, to get students thinking outside of the box:

- How could the item be made better?

Most design ideas are adapted from existing ideas, so this stage involves thinking about how things can be improved to be more efficient. - Can they draw it?

Before they start building the product and are still in the ideas stage, designers sketch their ideas on paper to present and communicate the design to others. - Tried and tested?

In this stage of the design process, product testing takes place. - Building models

Many big companies still begin their prototyping process using cardboard models, as it’s cost-effective and can be better than 3D drawings at showing how a product or product part will work and look. - Design specification

Now a design specification is needed. Several factors must be considered, for example, durability, hygiene, speed, size, maintenance and environmental standards. - Trial and error

This stage is a slow but steady process of making improvements, one change at a time. - Prototypes

In this stage thousands of prototypes are made. As well as making cardboard models, engineers use a prototyping technique called Selective Laser Sintering. The engineers’ drawings are sent to a 3D printer, which fuses nylon powder layer by layer into a fully working part. - Testing

In this stage prototypes are tested against the specification for hygiene, efficiency, durability, speed and noise levels. - Final product

The final product is manufactured and sold.

Marcus-Alexander Neil is UK Education Lead at Shell (@Shell).